|

NewChallengerStore.com PART #153030

PARTS INCLUDED: 1-Plastic Cover w/Velcro INTRODUCTION: This new accessory is a unique and stylish part

designed to add an awesome custom look to what otherwise would be a

relatively unattractive air filter box. Please note that the cover

is strictly decorative and is not intended to seal the factory air

box. PROTECTIVE LINER INFORMATION: Your new accessories will come

to you with a protective surface liner. Leave this liner in place

until the installation is complete to prevent finger prints and/or

possible scratches during installation. 1. The first step for this installation will be to prepare the

air box to receive the new accessory by removing the rubber gasket

attached to the air box top ridge. (Note: This gasket will not be

reused). 2. You will notice that the air box is fastened to the vehicle

with one single bolt located at the top front area of the box and

that this bolt has been sleeved with a steel sleeve encapsulated

with a rubber grommet. Remove this bolt. Then remove the rubber

grommet from the air box. (Note: This grommet will not be reused).

3. Lift the plastic box out of its valley in the engine bay just

enough to allow you to see the rubber grommet or grommets that the

plastic box seats into and remove those grommets. (Note: These

grommets will not be reused). 4. Set the air box back into position. The idea here has been to

effectively settle the air box to a lowered position by removing

these grommets thusly creating clearance for the new top plate

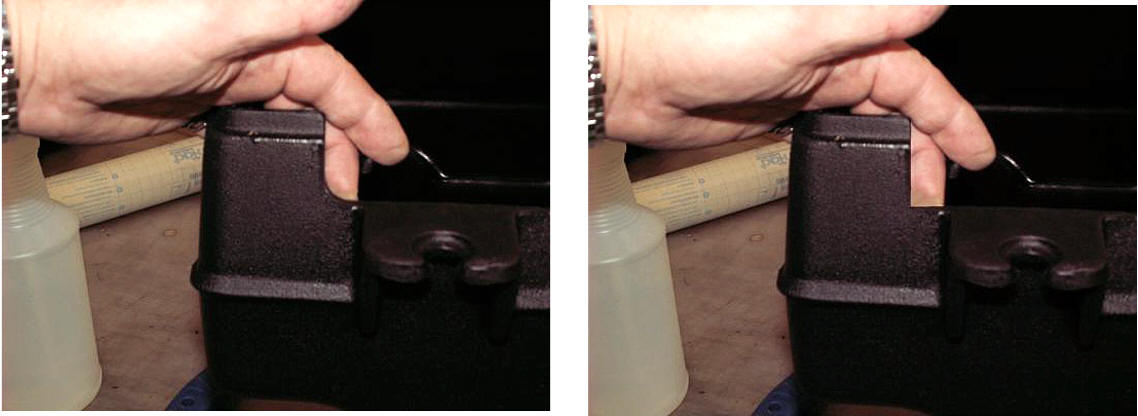

between the air box and hood. 5. You will notice that the air box contains a rounded corner at

the left side of the front opening as well as an area to the right

that will appear uneven along the top ridge. SEE PICTURE 1 & 2 6. Because this is uneven you will need to lightly file these two

areas in order to allow the new cover to fit comfortably into

position. First file the rounded corner to the left of the front

opening to a sharp 90 degree corner. Then file the top right of the

air box ridge so that it will no longer contain an uneven bump in

the rim and look nice and straight. SEE PICTURE 3, 4, 5 Although the new cover will not completely set flush to the top

of the air box due to is inconsistent shape and contour performing

these two light modifications will allow the new cover to sit very

nicely into place. 7. Once these procedures are complete, you can now set up the top

ridge for the new cover. You have been provided with a small piece

of scratch pad. Use this pad to thoroughly scuff the outer and inner

sides of the upper ridge that runs along the entire circumference of

the air box. SEE PICTURE 6. 8. Once this is done scrub the ridge with rubbing alcohol to

remove the dust and also to clean the ridge. Then swipe both the

inner and outer sides of the ridge with the adhesive promoter packet

provided. This packet is NOT a cleaner but and an adhesive

accelerator and must be used as such in order to successfully and

permanently attach the 32.5" length of furry Velcro supplied with

your kit. Once the ridge is prepared, peel the release liner

completely from the Velcro strip and place the end of the strip

along the ridge, starting at the front left side and then along the

entire box until you reach the other end. Trim away any excess if

necessary. At this point the Velcro will be standing straight up on

the ridge and you can now fold the Velcro over the ridge to the

inside of the box. (Tech Note: Before you fold the Velcro over, slit

the Velcro at all four corners with a razor blade. This will allow

you to fold the Velcro more easily and eliminate wrinkles in the

process.) Press firmly along the entire ridge to set the bond of the

Velcro. SEE PICTURE 7. 9. Now you are ready to install your new cover. You will notice

that your new cover has Velcro attached to the underside of the

covers frame and the window is slightly elevated. Remove the

protective liner from the window and then place the frame so that

the window will set into the air box ridge allowing the Velcro to

seat the window securing it in place. Although it should not be

necessary you may need to tweak the shape of the top cove a little

in order to achieve a nice contoured fit. 10. Remove the remaining protective liner. You have been provided

with a large 1.25" Washer head type bolt nut and washer. This bolt

has been proved as a replacement bolt for the factory one. Depending

on the production date of your Challenger this new bolt may slip

through the existing welded nut at the front of the air box, in

which case we have provided a new nut and washer to be placed under

the factory tab allowing you to secure the new cover’s mounting tab.

Then simply cover the new bolt head with the decorative chrome cap

cover. This cover will have a butyl putty attached, simply remove

the release tape and press it onto the bolt head to finish the

installation. (Note: Some Challenger models use a smaller bolt and

nut to secure the air box.) If this is the case you can elect to

either drill the factory bolt with a ¼" drill bit to allow the new

bolt to be set through the factory nut (recommended) or you can use

the original bolt to secure the new cover or you can re-tap the

factory nut with a ¼" 20 taping bit. If you have any questions during installation please call

American Car Craft at 727 861-1500. Additional Installation Tips from a customer… I installed the air box cover on my Mopar air box and thought I

would share my comments. Overall, I am very satisfied and perhaps my

suggestions would benefit others or allow you to update your

documentation. After a thorough review of the instructions, I found a couple of

deviations and enhancements that were beneficial during the process.

First and foremost, is the complete removal of the filter and box

from the vehicle as the majority of the work needs to be done on the

bench. This keeps plastic shavings and sanding residue away from the

filter, throttle body area and under-hood in general. Instead of a file, I used a very sharp utility knife to trim the

plastic as outlined in the instructions. After some test fits, I

also removed some plastic from the top ridge on the left side

(throttle body side) near the front to level out this area somewhat.

After smoothing the reworked areas and scuffing the top ridge, I

gave the entire box a thorough cleaning and drying to remove all

fine particles. After applying adhesion promoter, the Velcro strip

went on very nicely with the trim and slitting as instructed. After a little warming and flexing of the stainless frame, I

achieved a nice complete velcro seal all around the box. Note, I had

not yet removed any protective film from the cover. Next was the fitting and bolting of the box. I was not planning

to use the supplied washer and nut under the mount bracket as it

became evident that these would be hard to reach during future

maintenance, not to mention possibly dropping them into under-hood

voids. The supplied bolt allowing for the finished cap is standard

thread while the nut on the box mount is metric. I simply replaced

the factory push nut with a standard thread push nut. Then, I thought I would try the fitment with the stock grommets

in place which isolate the box from vibration, rattles etc. Using

plumbers putty at 5 points around the box and sheet of protective

plastic on top, I was able to determine up to 3/4 inch clearance

from top of cover to hood underside with hood closed. This confirmed

that on my 2011 Challenger, both grommets could stay in place. I purchased a Mopar decal part number 82212434. This is designed

to be placed on the inside of the quarter window glass and give an

etched-in appearance from the outside. After removing the underside

protective film, I affixed the decal in the tapered corner. See

photo. With cover in place, I removed the top layers of protective

film. To my surprise, the plexi panel had a smoke look despite the

product info describing it as clear. I would have opted for clear

had I known there was a choice although I am very satisfied with

result. Perhaps you could give future customers the option of clear

or smoke. Per the care sheet, I acquired all suggested cleaning and waxing

materials and applied the quick wax. Thanks again for the great service and speedy delivery. I will

refer others to your site as you have some super looking products

for many popular vehicles. Looking forward to a season of cruises and shows to "show off"

this beautiful accessory.

|